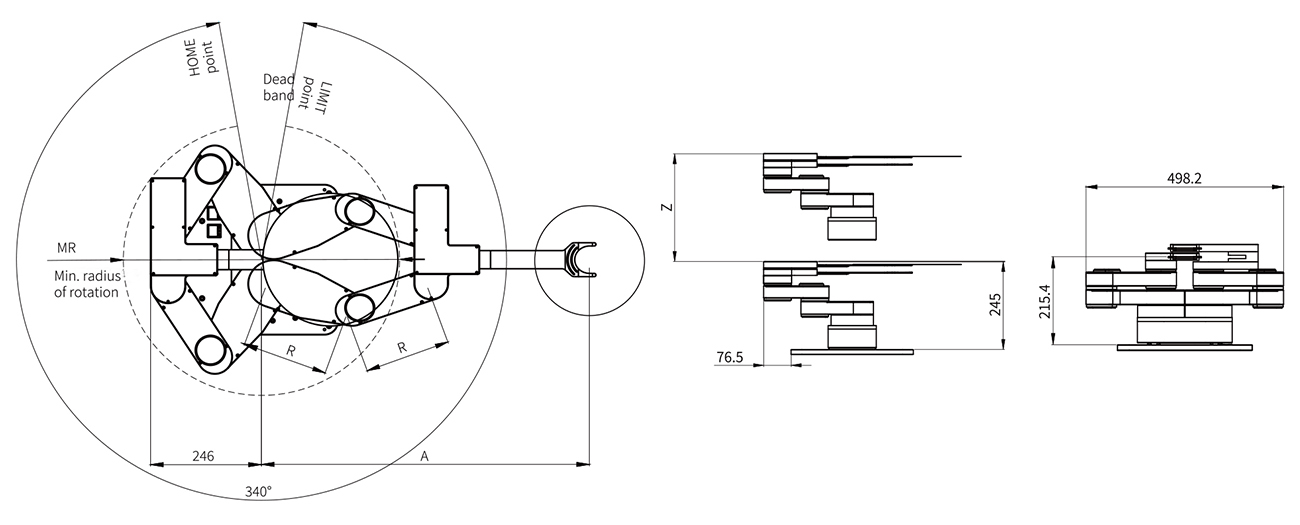

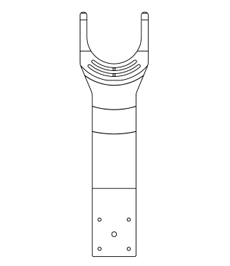

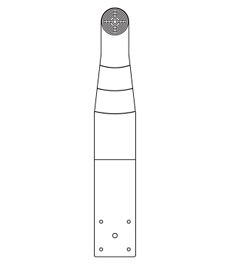

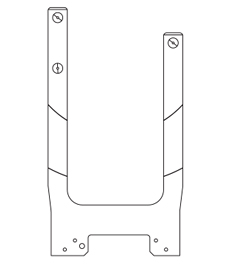

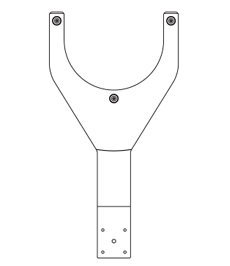

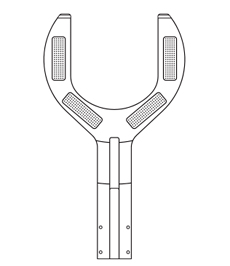

F: Fortrend W: Wafer P: PLP substrate M: Mask C: Cassette H: Humid R: Robot D: Arm Qty. S: Single arm D: Dual-arm A*: X(X:Number of Arms) | Axis-Z Height 240mm 300mm 400mm 500mm Z*XXX (Customized) LZ: Compact Lifting Height 240mm 300mm 400mm 500mm LZ*XXX(Customized) Dual-Z ZD600mm ZD700mm ZD800mm ZD*XXX (Customized) Module-based MZXXX | Drive Arm R Length 146mm 190.5mm 213mm Eccentric ER (optional) | Special Module Rta: Single arm FLiP Rta2: Double Arm Up FLIP Rta2: Double Arm Down FLIP RtaD: Double arm double FLip FR: wafer frame No Options | End-effector Type Ata: Vacuum suction Cta: Edge gripper Han: Clamp lift type Ber1: Contact Bernoulli Ber2: Non-Contact Bernoulli Customer Customization | Fork Type F: Original fork No Options | Wafer Size 4″ / 6″ / 8″ / 12″ N*: Non-wafer object | Matching Options M: M1: Opposite-shooting Mapping Quantity 1 M2: Opposite-shooting Mapping Quantity 2 M*: Mapping Quantity 1 No Options R: R: Original teach pendant No Options TX: T: Original Track axis X: TRACK axis effective distance/mm No Options | Special Customization Have: Special Model None: Normal Device |

二工位产品中心白底图1420x750.jpg)

二工位产品中心白底图1420x750.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(1).png)

(2).png)

.jpg)

.jpg)

.jpg)

.jpg)